Over the last decade, the world of spaceflight has become an increasingly competitive industry. We’ve seen private companies burst onto the scene with money and ambition – and we’re now at the point where scenes the Falcon 9 landing have become routine.

Through these incredible advancements in rocket reusability, we’ve seen the overall cost of getting into space drastically reduce. Once a rocket becomes reusable, the cost of actually launching the rocket becomes far more important – and one of the largest costs involved in launching a rocket is the fuel.

For SpaceX and their Falcon 9 rocket, they use liquid oxygen and a refined kerosene called RP1. The liquid oxygen needs to be cooled to cryogenic temperatures in order to compress and fit more into the rocket.

Although the liquid oxygen makes up more than two thirds of the overall fuel load, it’s by far the cheapest of the two fuels, coming in at just 20 cents per kilogram. RP1 on the other hand is a little bit less affordable.

When SpaceX were first starting out with the Falcon 9, they were paying around $2 for every kilogram of RP1. After renegotiating, they were able to lower the cost until it was closer to the price of jet fuel, at around 70 cents per kilogram. Overall, the cost to fill an entire Falcon 9 sets SpaceX back around $150,000. If SpaceX could reuse the entire Falcon 9, the cost to launch wouldn’t be much more than this – extraordinary considering what launches used to cost just 10 years ago.

But realistically, the Falcon 9 will never be fully reusable, since a brand new second stage has to be built for each flight. SpaceX has gotten very good at reusing the fairings, which saves them about 5 million dollars each mission. But SpaceX aren’t even consedering making the second stage reusable, as it now focuses on Starship. Because of this, the fuel costs will remain a small fraction of the overall launch cost. But for SpaceX’s Starship rocket, the fuel will be far more important.

Starbase, Texas

In just a couple of years, SpaceX turned a dirt field in Texas into an advanced testing site for their Starship rocket. With each and every test, SpaceX goes through an enormous amount of fuel. But what fuel does Starship use and how do SpaceX get it? In order to answer this we need to look at SpaceX’s overall mission.

With their Starship rocket, they want to take humans to Mars in a sustainable way – where they can set up bases and begin colonizing the planet. It takes an enormous amount of energy to get to and from Mars – but if we could produce fuel while we were there, it would cut the overall cost massively. That is why Starship will use methane and liquid oxygen as it’s propellants.

Both of these propellants can be found on Mars through the methane in the Martian atmosphere and the oxygen in the subsurface ice. Once we develop the technology that can efficiently convert all of this into usable Starship propellant, the hard work will be done. Methane is also a perfect choice since it’s the cheapest form of fossil fuel found on Earth. So how do SpaceX get liquid methane to their launch site?

Liquid Methane for Starship

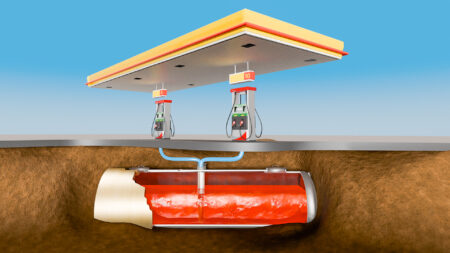

Liquefied natural gas which is mostly made up of methane can be found in reservoirs beneath the Earth’s surface. Mining companies use off-shore and onshore platforms to access and extract the gas from these reservoirs.

At this point, the LNG still contains nitrogen, water and carbon dioxide, so it’s piped to a treatment facility where these components are split up.

Once the methane is separated from the other elements, it gets piped to a liquefaction facility to be cooled. The methane which is still a gas at this point, gets cooled to -162 degrees where it turns into a liquid.

Once the methane is in liquid form, it takes up 1/600th of the volume. This is why cryogenic propellants are used on rockets, so they can be compressed to fit as much in as possible.

After the liquefaction process, the liquid methane is stored in insulated tanks until it’s ready to be shipped. The nearest LNG facility for SpaceX is in Brownsville Texas, just 30km away from their launch site. From there, SpaceX uses the transportation company GenOx to transport most of their liquid methane. They use state of the art trailers specifically designed to hold liquid methane.

For the trips to Boca Chica, each trailer can transport up to 13,000 gallons of liquid methane at a pressure of 70psi. Although this is a relatively high pressure, the methane is actually less dense at this stage than it will be when it’s in the Starship rocket – since it’s operating pressure is closer to 100psi.

Once the liquid methane arrives at the SpaceX site, it’s slowly pumped into the massive tank farm where SpaceX stores their propellants. It takes several trailers just to transport enough methane for one Starship – so methane deliveries are a common sight between each test.

Although SpaceX are currently outsourcing most of their propellants, it’s also common for propellants to be sourced on site. At the Kennedy Space Center, NASA has their own liquid oxygen plant operated by Air Liquide, which can liquify up to 265 tonnes of oxygen per day.

SpaceX are looking to create a similar setup at their Boca Chica site. According to Elon Musk, SpaceX will set up a wind farm at their facility to generate the enormous amounts of energy needed to separate oxygen from the air.

Liquid oxygen

This process involves compressing air to around 100psi and turning it into a liquid. This liquid air is then passed through various filters to remove things like water vapour and carbon dioxide which could freeze and block the machinery.

In order to separate the air into oxygen, nitrogen and argon, the liquid air is systematically brought up to the boiling point of each element. Since nitrogen has the lowest boiling point of all three, it turns back into a gas first, which can then be separated from the mix.

Then, the argon boils off at -186 degrees leaving behind pure liquid oxygen. This entire process requires a huge amount of energy, but when done at a large enough scale, the economics start to make sense.

This is why SpaceX can purchase their liquid oxygen from Air Liquide for as little as 20 cents per kilogram. But with SpaceX planning to build their own oxygen plant, they will need an enormous wind farm to power it and make it cost efficient.

Making their own oxygen

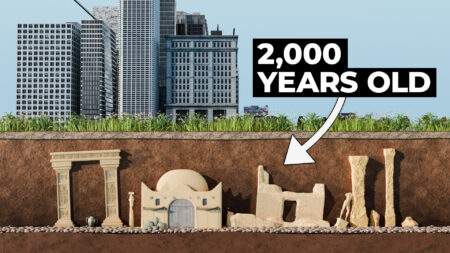

Alternatively, SpaceX could use the sabatier process of separating oxygen from h2O. This would be good practice for SpaceX, since they plan to use this exact method to obtain oxygen on Mars. Recently, people have noticed a lot of activity surrounding an old well on the SpaceX facility.

A large crane has been set up and people believe this could be the beginning of SpaceX’s own propellant facility. In order to be more carbon neutral, it makes sense that they would eventually start producing their own methane and oxygen using renewable energy sources. And if they can start producing their own fuels, they might even be able to reduce the cost for each Starship launch.

This world of propellant production is a new challenge for SpaceX, but it’s crucial that they develop the skills and technologies to do this on a large scale if they want to sustainably go to Mars.

In the past, SpaceX could rely on outsourcing their fuel and using pre existing infrastructure at the Kennedy Space Center. But now that they have their own facility in Boca Chica, they have to design and build all of these fueling systems from scratch.

When testing Starship prototypes at their launch site, SpaceX used to have a methane flare which would be used during each test. Since releasing methane into the atmosphere on its own contributes massively to global warming, the flare stack would burn the methane and turn it into CO2 before releasing it into the atmosphere.

Although this is much less harmful to the environment, the constant boil-off of methane during every test was a massive waste of propellant. In order to get around this, SpaceX started piping the excess methane into a recondenser, which cools it down and turns it back into a liquid. SpaceX can then store that methane in their tank farm and use it again for future tests.

Although they don’t recycle their liquid oxygen, it’s cheaper for them to just buy more and ship it to the launch site than it would be to recondense it after each test. Either way, it’s exciting to watch SpaceX revolutionize every little aspect of spaceflight with the aim to make rocket travel just as normal as air travel.

Space X’s Boca Chica launch site has at least one natural gas well. At one point there was some legal wrangling over who owned the rights to it. Was that ever settled?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

This is total BS start to finish.

They said that tankers bring methane between…

Not rocket launches,

,,, lol TESTS

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.