If you’re a SpaceX fan, you will be very familiar with this place, Boca Chica. For 24 hours every day, this small town in Texas is under constant surveillance from YouTube live streams, space photographers and curious people from all over the world, looking to experience Starship.

This incredible and sometimes creepy level of attention has been with Boca Chica ever since the first piece of stainless steel turned up. And rightly so, SpaceX is literally building the largest rocket ever made outside in a dirt field! But for a short period of time, SpaceX took over another location, which could have become the Boca Chica we know and love today. But what happened to this place?

The Florida Starship factory

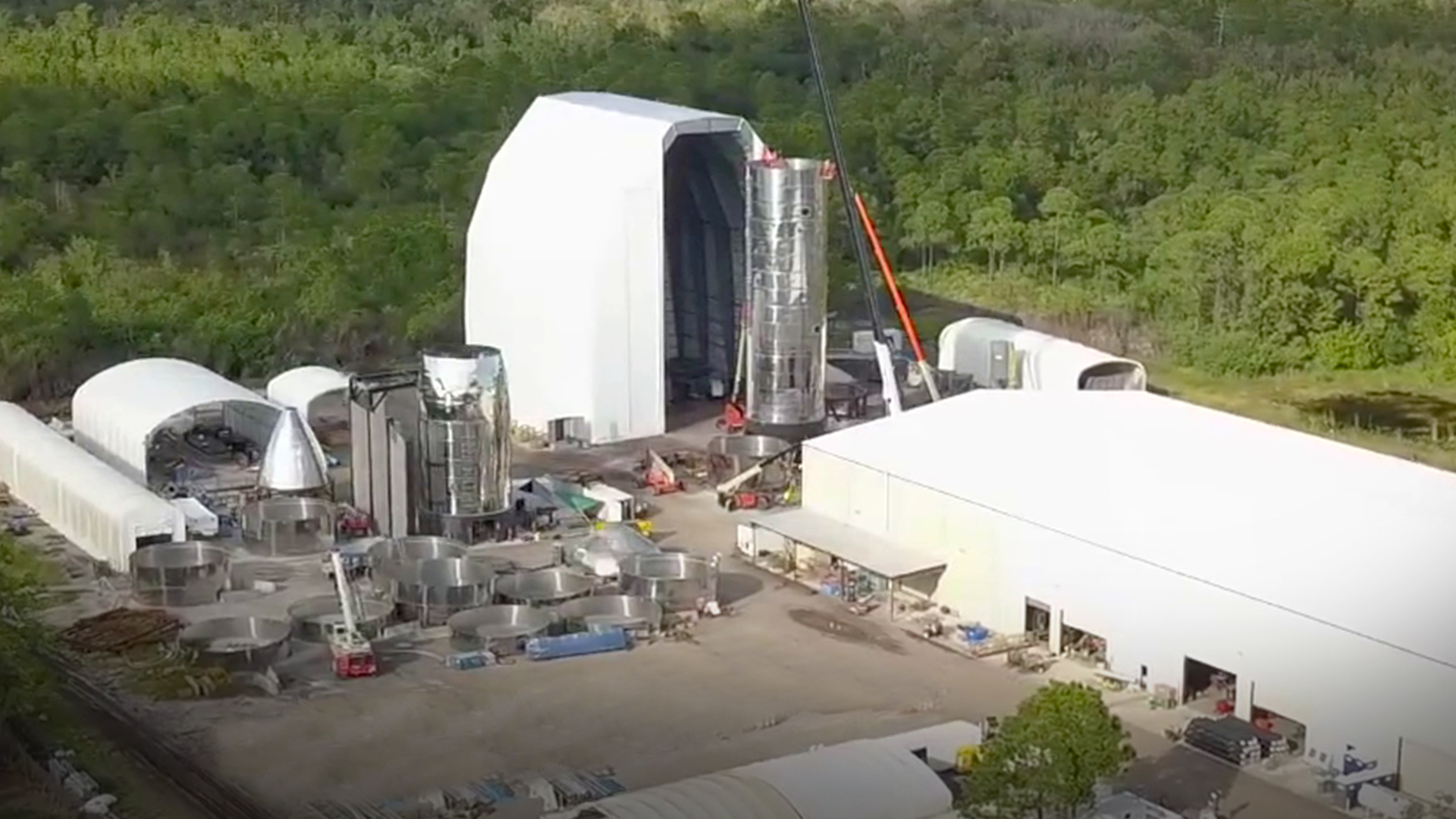

1,000 miles away in Florida lies a SpaceX site located near the Kennedy Space Center. This small construction yard in the city of Cocoa was set up when SpaceX first started building Starship back in 2019. Although both sites were set up for the same reason, Cocoa’s facility was extremely small – so small that you could fit almost seven of them into Boca Chica’s site.

Nevertheless, SpaceX knew that it was about to begin a very long journey with Starship. So in order to get started, a competition was set up within the company. The teams in Boca Chica and Florida were tasked with figuring out the best ways to actually make Starship. The rules were simple, any important breakthroughs discovered by one team had to be shared with the other team and whoever came up with the best solutions won the competition.

But what was the prize? Well, there was no prize. But for the workers in the winning team, it meant that they didn’t have to move a thousand miles across the country. This method of healthy competition turned out to be a great idea, perhaps even greater than SpaceX initially expected. But how did Boca Chica end up winning this competition?

Florida’s problems with Starship

One of the first problems Florida had was with their barrel machine. This is the machine that takes the rolls of stainless steel and transforms them into the 9 meter wide rings that make up Starship. The machine kept producing rings with slightly different diameters. So when it came time to stack them, the rings wouldn’t line up and the rings had to be scrapped.

Another major challenge with Starship was the welding, particularly on the bulkhead. These welds need to endure extremely cold temperatures and hold back the insane pressure going on inside the tanks. Evidently, the first attempts were not strong enough. But Boca Chica kept experimenting with different welding techniques, eventually automating a large chunk of the process, and it showed.

The welds on future Starships started to become cleaner and the vehicle itself started to look more sophisticated. But this was only a small part of what made Boca Chica great. Despite making good progress on Starship itself, it was the entire package of Boca Chica that won them the competition (building a restaurant out of old Starship parts also helped).

The competition wasn’t all about building the best Starship. You see, Starship is a rocket like no other, and because of that, it’s being built like no other rocket. Hence the dirt fields and factories made out of tents. But if SpaceX wants to send thousands of people to Mars, it will need to start mass producing Starships at a rate that the spaceflight world has never seen before.

Why SpaceX went with Boca Chica

And so, building the factories that actually make Starship turns out to be more difficult than making the rocket itself. This was where Boca Chica excelled. Having a massive expanse of land far away from most of civilization gave them the freedom to quickly set up buildings and experiment with many different manufacturing methods.

Florida on the other hand, was so space limited that the unusable steel rings would take up a huge portion of the land, or roughly the area of one Boca Chica restaurant. But how far did Florida actually get with their Starship?

This was only the second ever full-scale Starship prototype, with Mark 1 being built around the same time in Boca Chica. This prototype had already been destroyed during a test, so Mark 2 was Florida’s opportunity to show off their superior building skills. In many ways, Mark 2 looked like the better Starship, with much cleaner metal work and more sophisticated welds.

But how did the Florida team plan to actually test Starship? In Boca Chica, they already had a very basic testing facility and a road where Starship could be easily transported. In Florida, the plan to transport Starship was much more elaborate.

Getting to Pad 39A in Florida

SpaceX wanted to test Starship at the famous launch pad 39A, the same one that sent humans to the Moon. This plan sounds great, considering 39A already had existing infrastructure and was built to support rockets much larger than the Saturn V. But actually getting it to the launch site was a huge challenge.

Simply leaving the construction yard would involve cutting down trees and forming a brand new road through a field. From there, Starship would be towed down Grissom parkway and onto the main highway, all of which would need to be completely shut down by the police. Starship would then travel on the wrong side of the road in order to get to a small island on the Indian river.

From there, Starship would be loaded onto a barge and towed all the way to the Turn basin, where it would be unloaded and moved up to the launch pad. This elaborate plan was just weeks away from happening and utility workers had started raising power lines in order for Starship to pass through. Unsurprisingly, Florida’s Starship never left the construction site and the work there came to a grinding halt. But what ever happened to this place and the Starship that was being built?

After thoroughly winning the competition, SpaceX started throwing everything into Boca Chica. At the start of 2020, SpaceX held a career day, where hundreds of young hopeful engineers turned up to apply for a job. After this, Boca Chica’s workforce doubled to around 500 employees and SpaceX began operating 4 shifts a day, creating a constant 24 hour work cycle.

Florida employees

This was also a good excuse to break out the SpaceX mariachi band. Since then, Boca Chica has been completely taken over by SpaceX and turned into its own city. The workers at the Florida site were either offered a job in Boca Chica or at other SpaceX facilities in Florida.

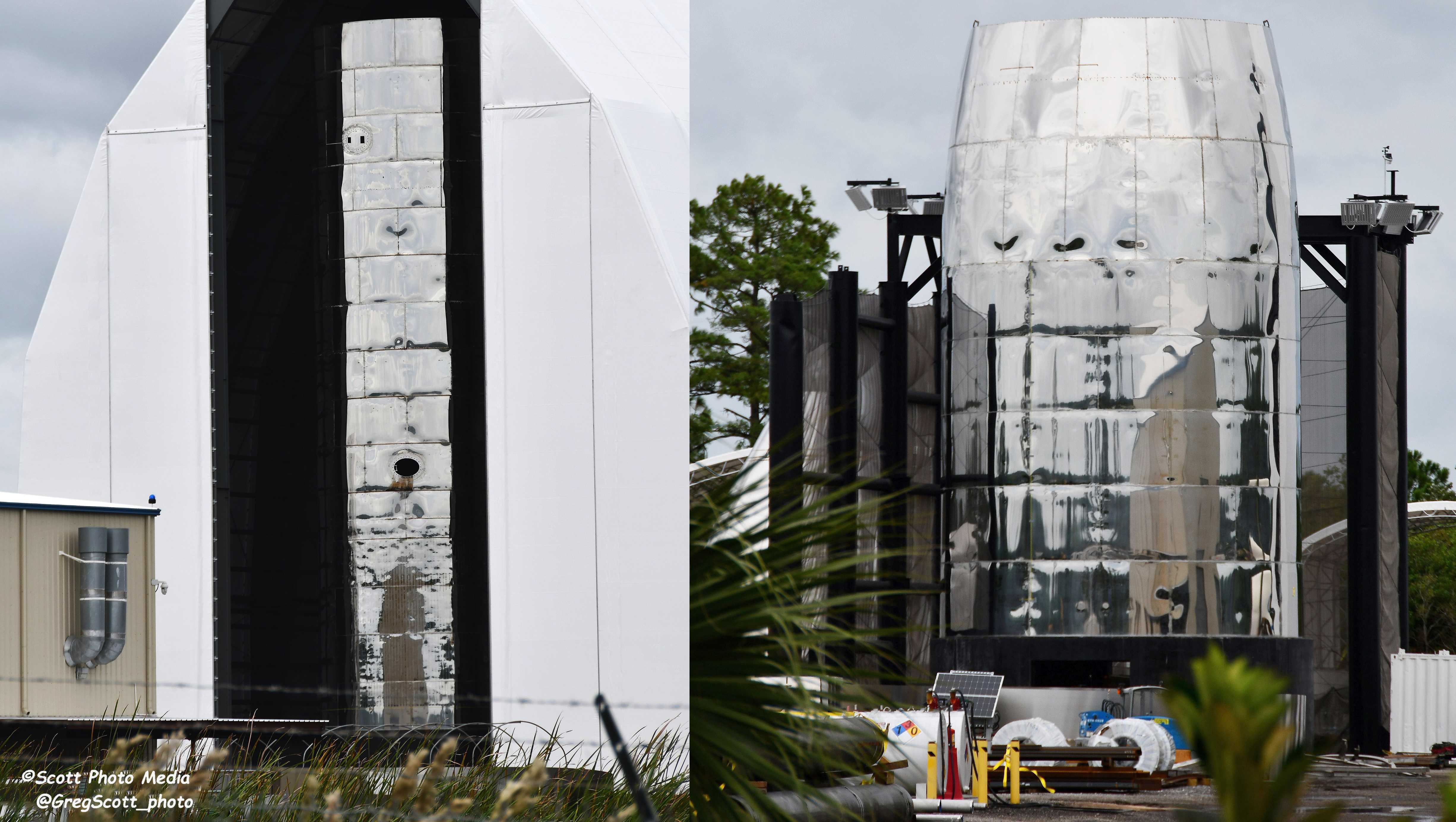

SpaceX now uses the Cocoa site to manufacture Starship’s heat shield tiles, in a building they call the Bakery. The remains of Starship Mark 2 were slowly demolished with some equipment being shipped over to Boca Chica. But this isn’t the last we’ll see of Starship in Florida.

20km away from their old Starship site lies a much larger area of land which SpaceX has taken over. Home to one of their Falcon 9 refurbishment hangars, this site will soon feature an enormous state of the art factory, purpose-built to make Starships.

This factory will be larger than all of Boca Chica’s tents combined, and the crazy thing is, this is only part of the factory. Future plans show that the factory will be extended and almost doubled in size. But how will these Starships be launched and tested?

Luckily, this new facility is located right next to the Kennedy Space Center, where Starship and Super Heavy could easily be transported all the way up to the launch pad. To add to the excitement, SpaceX has already begun constructing the enormous tower that will launch and catch future Starships.

These giant tower sections will be built at the new facility and driven out to the launch pad at 39A to be stacked, exactly like they were in Boca Chica. And so, we now have a completely new Starship facility to be curious about.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?