It was December of 2018 when BocaChicaGal first shared these images of what would become Starbase, the home of Starship. Although it wasn’t known at the time, this tiny bit of land in a quiet village in Texas would go on to become one of SpaceX’s most important facilities.

But almost 400 miles away in another quiet Texan town lies a SpaceX facility that has played the supporting role in all of SpaceX’s success. This is the story of the McGregor testing facility. We’re gonna look at how this place got started way back in 1940 and how SpaceX used it to develop some of the most advanced technology in spaceflight.

McGregor facility opens

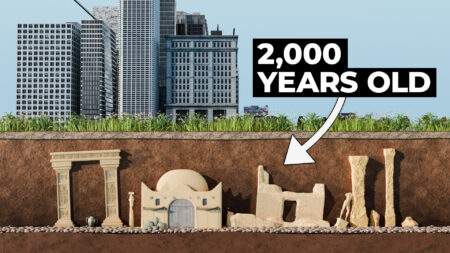

In 1941, the US joined World War 2 and it suddenly needed an enormous amount of bombs. The US chose various sites across the country to set up large scale bomb factories – and McGregor Texas was chosen as one of those sites.

This site was to be known as the Bluebonnet Ordnance Plant. Within several months, a factory was set up and McGregor started producing various kinds of bombs, some being as large as 1,000kg.

McGregor’s population before the war was only around 2,000. But thanks to the factory, this number skyrocketed with all of the workers who moved there with their families, just like how SpaceX is transforming Boca Chica and the surrounding areas.

Bluebonnet continued producing bombs throughout the war and at its height, employed over 5,000 people. Once the war was over though, the factory was no longer needed and production was shut down soon after. For a few years, parts of the factory remained open and started producing furniture and kitchen stoves.

First rocket company moves in

But it was in the 50’s that McGregor would plant its roots as a rocket facility. It was eventually bought by the US Air Force and then owned by the company Rocketdyne, who would go on to test and produce thousands of engines during the Apollo program.

After being handed back over to a munitions company for about 20 years, the facility was finally taken over by an up-and-coming private space company, looking to develop heavy lift vehicles. But this company wasn’t SpaceX.

SpaceX takes over the McGregor facility

After 20 years, the McGregor facility was being handed over to a new private space company, looking to revolutionize space travel. Set up in 1997, Beal Aerospace came before SpaceX and took over the McGregor site to act as a testing facility for their rocket engines.

In the year 2000, they successfully test fired their BA-2 engine, the largest rocket engine ever made since the Saturn V’s enormous F-1 engines. However, later that year the company closed down after NASA decided not to invest in them – and so the McGregor facility was once again left empty.

Next in line though was SpaceX who took over the site just 3 years later to begin testing of their Merlin engine, which was to be used on their Falcon 9 rocket. In the first several years of owning the facility, SpaceX expanded it massively – doubling the amount of land space and growing the employee count from just 3 people to 140 by the end of 2011.

By this point, SpaceX had already flown the Falcon 9 successfully, but the next challenge was making it land. And so, SpaceX started laying down concrete for its first ever launch and landing pad.

From here, they were planning to fly their Grasshopper rocket – a Falcon 9 style rocket that would be used to practice vertical landings. In September 2012, the rocket was on the pad ready to perform its first flight. Years of work had been leading up to this moment, and the future of the company counted on this thing working.

But… that was it… It was a tiny hop, but an important one. The Grasshopper rocket went on to perform 8 successful flights, each one flying higher than the last. After scaring a few cows along the way, SpaceX then went on to fly a larger rocket that had much more resemblance to the Falcon 9 we know and love today – again performing multiple successful flights and one slightly less successful.

Developing Falcon 9 landings

By 2015, Falcon 9 flights were becoming more and more common – and with 10 engines on each rocket, McGregor was constantly testing new engines that came off the manufacturing line. SpaceX had grown the facility from 256 acres to over 4000 and were performing an average of two engine tests every day!

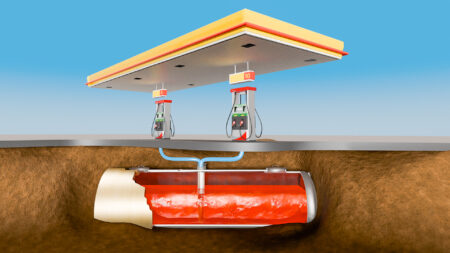

Back then, Falcon 9’s weren’t being reused just yet, so every rocket that went into space was brand new. This meant that they needed a test stand to fire the entire first stage before each flight. These tests were full duration, meaning the rocket was fully fueled and fired its engines for the complete length of the mission while being held down.

These tests used to be performed on the iconic tripod stand, which was built by Beal Aerospace in the 90’s. However, as the Falcon 9 developed, it became much more powerful – too powerful for this test stand. And so, a new one had to be built to support this immense amount of force.

The McGregor facility continued to be super important for the Falcon 9’s development. Now, the Falcon 9 is one of the most reliable rockets in the world, and one of the only rockets that reuses its engines. In order to make them robust enough to survive multiple flights, SpaceX went through years of engine testing and development, and they haven’t ever stopped.

One of the only ways to truly understand the limits of your engine is to push it until it blows up. And so McGregor became not just an engine testing facility, but an engine explosion facility. But this method of engine testing is nothing new.

Back in the Apollo days, NASA was testing the enormous F-1 engine which would eventually take humans to the Moon on the Saturn 5 rocket. Engineers were having problems with this engine, since it kept developing something called combustion instability, where the two propellants in the thrust chamber would burn unevenly and cause massive pressure swings.

These pressure swings were big enough to rip the engine apart, which is exactly what kept happening. Don’t forget that all of these engines together would burn through an entire olympic swimming pool’s worth of fuel in just 2 minutes.

Once NASA had designed new parts to fix this problem, they wanted to test that the combustion instability wouldn’t occur. So to exaggerate the conditions that cause the instability, they placed a bomb in the center of the injector plate and set it off as soon as the engine fired up.

This test was dramatic, but it successfully proved that the engine could now deal and normalize such intense pressure swings.

But in order to find these problems before humans were ever launched, NASA had to blow up many F-1 engines to discover the cause of the problem. This is exactly what SpaceX does at McGregor. And now that SpaceX is developing Starship and its Raptor engine, McGregor has never been more important.

SpaceX Raptor engine development

Over just the last few years, we’ve seen this engine go through a number of aesthetic changes. Raptor 2 now produces 230 tons of thrust compared to the Raptor 1, which only produced 180 tons of thrust. On top of that, Raptor 2 has cut the manufacturing costs in half.

With more and more engines being produced, multiple engines are being tested at McGregor everyday. Thanks to cameras placed by NASASpaceflight, we can see every single time that SpaceX performs any kind of engine test, and every time one goes wrong.

The incredible thing is that when an engine does blow up, it usually only takes SpaceX a matter of hours to get right back on the saddle and continue testing.

SpaceX has 5 test stands at McGregor specifically for testing Raptors. Two of them are horizontal test stands, which require less protection since the flame is diverted away from the engine and equipment.

But the vertical test stands provide a more realistic test of how the engine will behave during launch. The final Raptor test stand is located on the massive tripod stand, the one that Falcon 9 first stages used to be tested on until they became too powerful. Well, SpaceX renovated that test stand in 2019 and made it much stronger, in order to start testing Raptors.

Raptor testing happens every day now at the McGregor site, causing some disturbances to nearby residents. Over the years, people living near the site have had to deal with the low rumbles every day. Some people even say the sounds have caused damage to their properties.

SpaceX made an agreement with the city of McGregor to not perform engine tests after 11pm. To add to this, if they perform a test between 9pm and 11pm, they will get a fine of $10,000, then $15,000 and $25,000 for a third time, with a reset each year.

With SpaceX seriously ramping up Raptor production in the last few years, McGregor has become even more important to SpaceX’s overall goal of getting humans to Mars. With the idea to build and mass produce hundreds of Starships, SpaceX will require an enormous amount of engines.

And so for the first time, McGregor will now become a place where engines are actually made. SpaceX announced that it would be building a brand new factory on the McGregor site specifically for mass producing Raptor 2 engines.

With this factory, SpaceX should be able to produce around 2 to 4 engines every day or around 800 to 1000 per year. The larger Raptor vacuum engines will continue to be made back in California since not so many of them are needed for a fully stacked rocket. All experimental and development engines will also come from the factory in California as SpaceX continues to squeeze even more power out of Raptor.

So although McGregor might not have the same level of attention as Boca Chica or Florida, it has been SpaceX’s playground since day one, allowing it to experiment and develop its rocket engines. It seems fitting that after beginning life as an explosives factory, the McGregor site is once again producing more explosions than ever.

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Please check your numbers on fuel flow. The Saturn V consumed 24,000 pounds of fuel a second. That works out to one Olympic size pool every 2 seconds not 2 minutes.