On the 24th of April, 1990, Space Shuttle Discovery launched the Hubble telescope into orbit, marking a significant milestone in space exploration. This groundbreaking mission aimed to unveil the mysteries of the cosmos and provide humanity with unprecedented views of our universe. The anticipation and excitement surrounding this event were palpable, as scientists and enthusiasts alike eagerly awaited the extraordinary discoveries that Hubble would unravel.

This monumental launch heralded a new era in space observation. Equipped with advanced imaging capabilities, Hubble promised to capture mind-boggling images that would redefine our understanding of the cosmos. Its position in orbit, far above the obscuring effects of Earth’s atmosphere, offered a unique vantage point to gaze into the depths of the universe.

Hubble’s achievements

After 30 years of dedicated service, Hubble has surpassed all expectations, leaving an indelible mark on our understanding of the cosmos. It has become synonymous with captivating and awe-inspiring imagery, capturing the hearts and minds of people around the world. Hubble’s remarkable legacy is not just measured in numbers but in the profound impact it has had on scientific discoveries and our collective sense of wonder.

Throughout its lifetime, it has taken millions of amazing pictures. In 1995, it captured this image of the famous Pillars Of Creation nebula – and in 2016, it discovered the most distant galaxy in our universe. Despite becoming the most famous telescope in the world, it’s easy to forget that it was almost a complete failure.

Hubble’s mirror problem after launch

However, behind the curtain of Hubble’s extraordinary achievements lies a remarkable tale of perseverance. Shortly after its launch, scientists encountered a significant hurdle—a small defect in Hubble’s mirror that caused the telescope to produce blurry images. This unexpected setback posed a formidable challenge to the mission’s success and cast doubt on the potential of this groundbreaking endeavor. Nonetheless, the dedicated team of scientists and engineers rallied together to devise a solution, ultimately leading to the intricate repair mission that rectified the flaw and restored Hubble to its full potential.

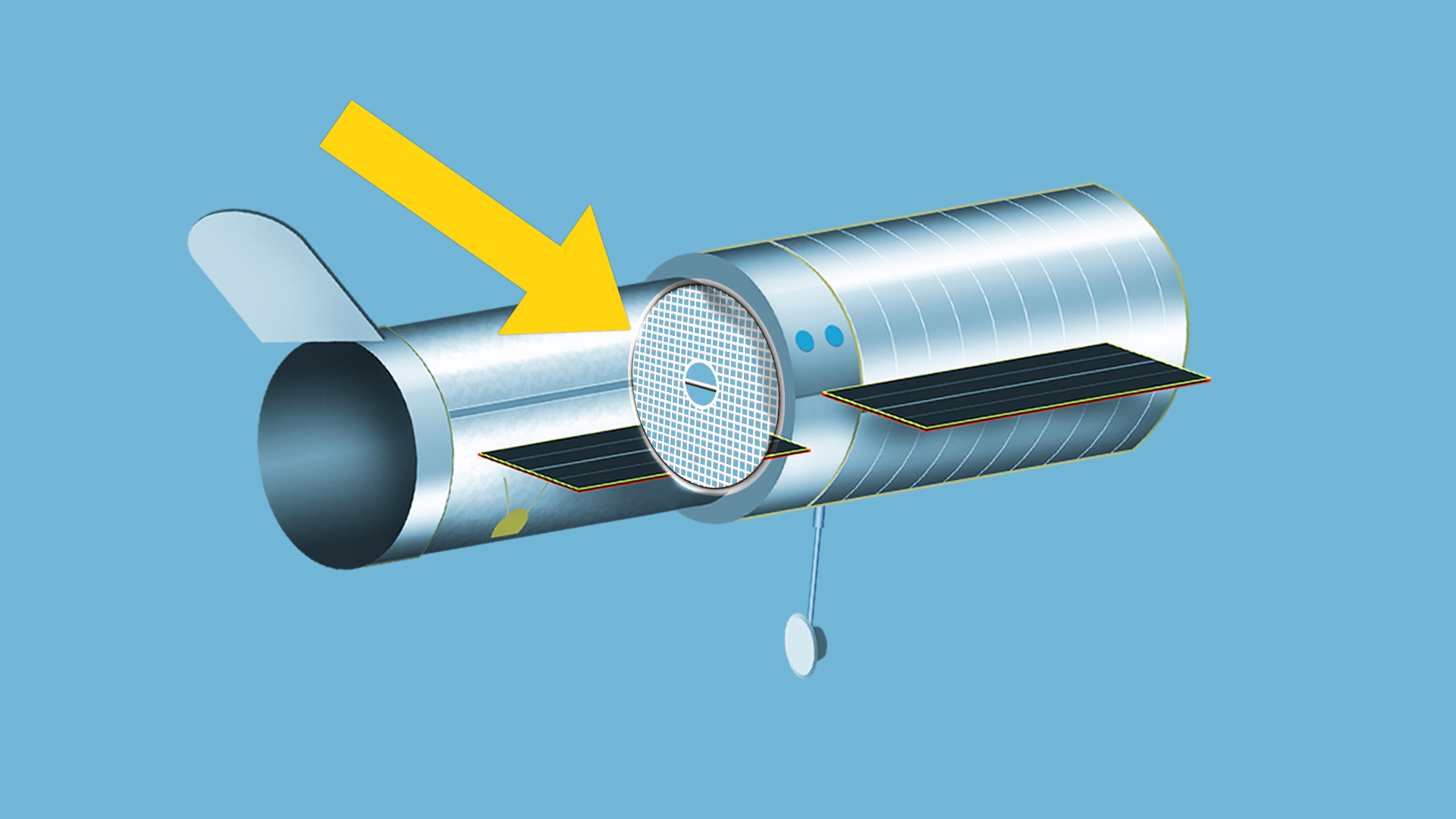

The flawless precision of Hubble’s 2.5-meter-wide mirror is paramount to its ability to capture the breathtaking images we have come to cherish. It serves as the heart of the telescope, requiring meticulous craftsmanship to ensure optimal performance. The painstaking efforts invested in its design and calibration have allowed Hubble to peer deep into the cosmos, capturing intricate details and unveiling the celestial wonders that lie billions of light-years away.

The main mirror captures the light before reflecting it onto a much smaller mirror, which serves as an intermediary in the complex optical system of the Hubble telescope. This intricate arrangement allows for precise manipulation and fine-tuning of the incoming light, optimizing the quality of the observations. From there, the light is further reflected onto Hubble’s various imaging instruments, each designed to extract specific scientific insights from the captured data.

If the mirror’s curve was perfect, light that hits any part of the mirror would focus exactly onto the same spot, ensuring crisp and sharp images of distant celestial objects. The engineering precision required to achieve this level of accuracy is truly remarkable, as even the tiniest deviations can have profound consequences for the performance of the telescope. However, due to the mirror’s defect, a minuscule departure of a mere 2000 nanometers (1/50th the thickness of a human hair), light hitting the inner parts of the mirror was being focused in a different place, causing blurring and compromising the telescope’s capabilities.

The shape and curvature of the mirror were meticulously crafted during a meticulous manufacturing process that spanned over a decade before the Hubble telescope was launched. This lengthy duration allowed for exhaustive testing and calibration, aimed at ensuring the mirror’s optimal performance under the demanding conditions of space.

The backup mirror

What most people don’t know is that an identical backup mirror was also constructed as part of a comprehensive risk mitigation strategy. This precautionary measure was put in place to safeguard against any unforeseen circumstances that might compromise the main mirror’s functionality. The development and production of the backup mirror were conducted in parallel to the main mirror’s construction, reflecting the cautious nature of the mission planners and their commitment to ensuring the success of the Hubble project.

So how did this flawed mirror manage to make its way into space? And why wasn’t the backup mirror ever used?

In 1977, NASA secured the much-needed funding to initiate the construction of the groundbreaking Hubble telescope, embarking on a mission that was estimated to cost approximately $300 million. To bring their vision to life, they engaged the expertise of Perkin-Elmer, a prominent optics company, which stood out as NASA’s top choice due to their innovative approach involving custom-built computer-controlled polishing machines. These cutting-edge machines would play a pivotal role in grinding the mirror to its precise and demanding shape.

The technological prowess of the era was put to the test as the mirror had to be polished with an astonishing level of precision, requiring an accuracy within the realm of a mere 10 nanometers. Recognizing the importance of contingency planning, NASA wisely stipulated that Perkin-Elmer subcontract the production of a backup mirror to another renowned company, Kodak. Known for their proficiency in crafting camera equipment and optical lenses, Kodak seemed like a fitting collaborator for this crucial endeavor. Interestingly, during this stage, Kodak and Perkin-Elmer proposed the idea of mutually examining their respective mirrors to ensure flawless quality, although, regrettably, this crucial step was not executed.

Building the mirror

With NASA’s budget secured for the ambitious Hubble project, Perkin-Elmer forged ahead with their meticulous design and manufacturing processes, commencing the construction of the main mirror in 1979. Starting with a blank sheet of ultra-low expansion glass, they embarked on the arduous journey of transforming it into a mirror of unparalleled capabilities, adhering to the rigorous specifications and demanding tolerances set forth by the project’s engineers. The painstaking polishing process alone spanned a grueling two years, as Perkin-Elmer’s dedicated team labored meticulously to attain the mirror’s intended shape.

The glass was then washed and covered in a reflective aluminum coating – and so, the mirror was born. Over the next few years, the mirror went through a series of tests to show that it could handle the intense vibrations of a rocket launch and survive the harsh conditions of outer space. But in order to test if the mirror had been polished to the correct shape, they used something called a null corrector.

This was essentially a specialized lens equipped with a series of precisely positioned mirrors, carefully employed to ensure the accurate and precise focusing of the incoming light onto the telescope. A laser was directed through the null corrector, illuminating a lens that contained a wavefront—an optical representation of the coherent beam of light. In an ideal scenario, the lines from the wavefront would appear perfectly straight, devoid of any contour lines or irregularities, signifying the precise alignment and focus of the telescope.

Testing mistake

However, during the setup of the null corrector, an unintended misplacement of one mirror occurred, fortuitously compensating for Hubble’s inherent flaw. Surprisingly, this configuration led to misleading results, erroneously indicating that Hubble’s primary mirror was flawlessly shaped, despite the presence of actual imperfections. Meanwhile, the completion of Kodak’s backup mirror was approaching, but since NASA had chosen to proceed with Perkin-Elmer, Kodak’s mirror remained uncoated with its intended reflective material and was securely stored for future use.

Unfortunately, this inconspicuous error evaded detection throughout the rigorous testing program. In 1990, the telescope was finally launched, sparking great excitement and anticipation. However, the initial images received from Hubble unveiled a disheartening truth—the presence of blurriness and distortions that clearly indicated the telescope was not performing as expected. This revelation dealt a devastating blow to the engineers and scientists who had dedicated their expertise and efforts to the Hubble project.

After decades of extensive efforts and a staggering amount of financial investment, it appeared that Hubble would be forever remembered as an ignominious symbol of a failed space endeavor. To compound the already prevailing distress, the backup mirror meticulously crafted by Kodak underwent rigorous testing, affirming that it had indeed been polished to the precise shape required.

Had Perkin-Elmer willingly agreed to carry out a thorough examination of both mirrors, it is highly probable that the error would have been detected prior to Hubble’s momentous launch. Despite the remarkable perfection of the Kodak mirror, it was rendered essentially ineffectual since replacing the primary mirror in the unforgiving environment of space was a formidable undertaking.

Fixing the mirror’s defect

Nevertheless, the ingenious design of Hubble incorporated an inherent repairability aspect. Nestled within the depths of the telescope resided Hubble’s five instrument bays, each encompassing a specialized box housing a scientific instrument capable of conducting a myriad of measurements. This modular configuration bestowed Hubble with the flexibility to extract and substitute instruments with more advanced counterparts over the course of its operational lifespan.

Fueled by unwavering determination, NASA embarked on an endeavor of remarkable ingenuity—an undertaking that involved conceiving a solution compact enough to fit within one of the instrument bays and rectify Hubble’s faulty mirror. Although the polishing machine had inadvertently erred, it had done so with an uncanny precision, providing NASA with invaluable insight into the precise nature and extent of the mirror’s imperfections.

They came up with a compact set of mirrors and lenses that would take the light and refocus it onto Hubble’s various instruments. This new instrument called COSTAR, featured two small mirrors that extended out from the instrument. One mirror was completely flat and simply reflected the light onto mirror 2 which was curved in the exact opposite way to Hubble’s main mirror. This put the light back into the correct form and focused it onto the instrument.

After $50 million and 2 years of development, COSTAR was ready to be launched. The extensive research and engineering efforts undertaken by NASA’s dedicated team were aimed at ensuring the success of this intricate instrument. Each component was meticulously designed and tested to withstand the extreme conditions of space and precisely compensate for Hubble’s mirror defect. The engineers and scientists involved in the project were eagerly awaiting the moment when COSTAR would embark on its mission to save the Hubble telescope.

On the 2nd of December 1993, the Space Shuttle Endeavour made its historic journey into space, carrying seven astronauts, including specialists trained to install and deploy COSTAR. The significance of this mission was palpable as the fate of the Hubble telescope hung in the balance. The crew members, equipped with extensive training and expertise, performed a carefully orchestrated 7-hour spacewalk, showcasing their remarkable skills and determination. With utmost precision and caution, they removed one of Hubble’s instruments, making room for the installation of COSTAR. This critical task required meticulous attention to detail and flawless execution to ensure the successful integration of the corrective instrument into the telescope’s intricate system.

The work was incredibly delicate but thanks to the clever engineers on the ground, the repair job was a success. It took several more weeks for COSTAR to fully deploy. But when Hubble finally sent back new images, they were incredibly clear and showed that the repair mission had worked perfectly. The scientists that worked so hard to create this telescope were overjoyed and relieved that Hubble could now start doing what it was designed to do.

Over the next few decades, Hubble would go on to make incredible discoveries, capturing beautiful images and showing us the universe in a way that had never been seen before. The telescope was regularly serviced by the Space Shuttle and in 2009, COSTAR was removed from the telescope. By this point in time, the other instruments had been updated to have their own optics built in, so Hubble’s original savour was no longer needed.

The kodak mirror remained in storage at Perkin-Elmer’s facility until the year 2000, when it was transferred to the National Air and Space Museum in Washington D.C. Despite never being used, this mirror was in fact perfect and would have saved NASA millions of dollars and countless hours of wasted time.

However, the incredible engineering required to fix Hubble shows just how capable we are as humans. Over the years, Hubble’s systems have become less reliable and the end is in sight for this iconic telescope. New telescopes will come along with more advanced imaging systems, but we will always remember the incredible knowledge that Hubble gave us.

What a bullshit article

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!