It’s 1913, you’re driving along in your brand new Ford Model T – the roof is down, the sun is out, life is good. But you’re running out of gas!

Luckily, the world’s first gas station just opened up around the corner – so you pull in and fill up your car in seconds. This was a brand new concept at the time, and it planted a seed that would go on to change the world.

The car market exploded, and soon, more than 150,000 gas stations had been built all across the country, giving people the freedom to travel like never before. Since then, gas stations went from being dangerous fire hazards at the side of the street to ultra efficient pit stops, pumping out 3 billion gallons of fuel around the world every day.

In order to understand how gas stations work today, we need to go back to a time before they even existed. Most people didn’t have cars yet, but kerosene was being widely used to power lamps and stoves. To get it, you’d go to a hardware store where an employee would pour it straight into a can and sell it to you.

Inventing the fuel pump

When cars started coming along, the kerosene would go from the store into a can and the customer would pour it into their car using a funnel.

This was slow and dangerous – and so there needed to be a safer and more efficient way to pour kerosene.

That’s when American inventor Sylvanus Bowser came up with the fuel pump. This was a hand-driven mechanism that squeezed kerosene from its container through a one-way valve and out of a nozzle on top. One full crank would dispense exactly 1 gallon of fuel.

Curbside gas stations

Soon, these pumps started being placed on city streets, allowing cars to be filled up conveniently by an attendant.

But customers had no idea if they were actually getting all of the fuel they paid for. And so, a few years later, the visible fuel pump was invented. The attendant would first pump the fuel up into a glass tank on top of the pump, measuring it to an exact amount. Then, by opening a valve, gravity would drain all of the fuel into the customer’s car.

These small curbside gas pumps worked well in the early days, when in 1900, there were only 8,000 cars in the whole of the US. But just 12 years later, that number increased to 1.2 million, and suddenly, cars were everywhere.

Traffic jams started building up around every pump, and the small 50 gallon tanks couldn’t cope with the demand. Worst of all, having all of the fuel stored above ground meant that things could go catastrophically wrong.

First dedicated gas station

And so, in 1913, the Gulf Oil Company opened up the first dedicated fueling station in Pittsburgh. Instead of a single pump, they placed a much larger storage tank underground and connected it to 6 pumps, allowing multiple cars to fill up at the same time. On its first day, it sold just 30 gallons of kerosene – but word quickly spread, and by the end of the week, it was already selling 350 gallons per day for around 27 cents per gallon.

Similar gas stations started opening up all over the country and the car became the ultimate key to freedom.

Kerosene to gasoline

But by the 1920’s, most cars had switched from kerosene to gasoline, since it burned more easily and was more efficient – but this caused a new problem, vapour.

Kerosene had a flash point of 38 degrees, meaning that it wouldn’t emit flammable vapour until it reached that temperature. But for gasoline, the flash point was -40 degrees, and so it was constantly emitting flammable vapour into the air. This vapour would build up inside the tanks and pollute the air whenever someone filled up their car.

In order to turn gas stations from dangerous fire hazards into efficient self-service pitstops, some clever engineering had to happen. Up until this point, cars were always filled up by a trained attendant. But as competition started to rise, gas station owners were desperate to lower their prices. And so, in 1947, Frank Ulrich opened the first ever self-service gas station.

By getting rid of the need for an employee, he was able to lower the cost of gas from 23 cents per gallon to just 18 cents per gallon, drastically undercutting the competition around him. It was an instant hit, and ended up selling half a million gallons in its first month.

But the idea of customers handling their own gasoline seemed dangerous and so self-service stations were banned throughout most of the country. The problem was, customers had no clue when their tanks were full, and so gasoline would often spill out all over the gas station.

Gas station engineering

That’s when engineers came up with the automatic shut-off valve. This was a simple mechanical float placed inside the nozzle that would rise and shut off the flow of fuel once the car was full.

A mechanical flow meter would measure the amount of gasoline passing through and it would control the money wheels and gasoline measurement depending on the price per gasoline which was set below by 3 pin devices. To change the price per gallon on these old mechanical pumps, someone had to unlock the pump face, then select a different set of gear ratios, altering the fuel flow multiplier.

But deep underground, there was still one huge problem. Inside the huge storage tanks, gasoline vapour would build up, forming a layer of flammable gas. When it came time to refill the tanks, the vapour would get pushed out into the atmosphere, creating an almighty fire hazard. On top of that, the steel tanks would corrode over time, leaking gasoline into the surrounding soil.

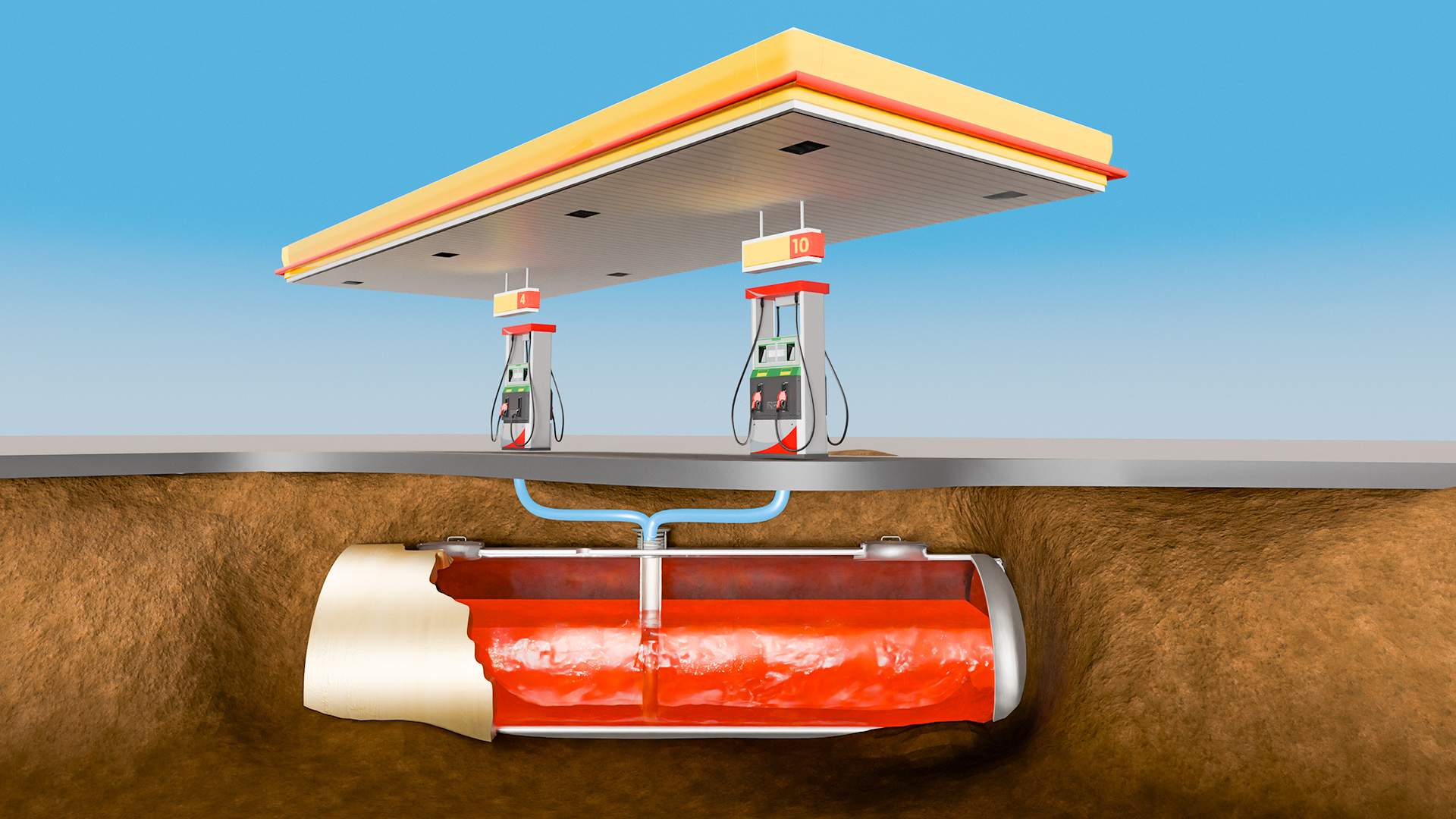

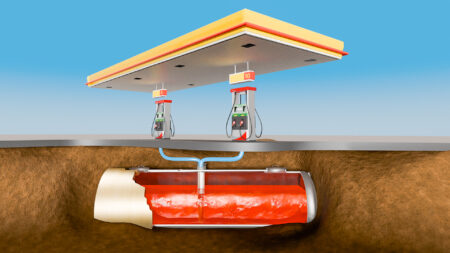

Nowadays, these underground gas tanks are made from fiberglass and they have dozens of hidden engineering details that all go into making them safe. Here’s how it all works.

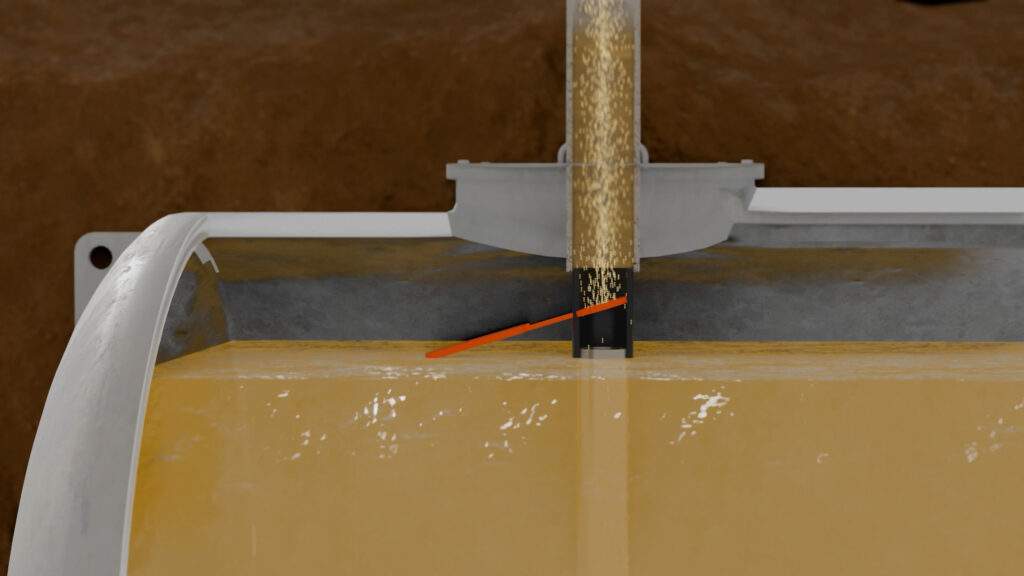

When a truck comes to refill the tanks every few days, it connects to a valve on the surface and gasoline starts flowing into the tanks. As the level within the tank rises, a flapper valve flips up and stops the flow of fuel once the level reaches around 95%, making sure it can never be overfilled.

To take care of the vapour, the truck connects to a 2nd valve at the top of the tank. As the gasoline is pumped from the truck into the tank, the vapor exits through this secondary valve and gets pushed back into the truck. That vapour is then returned to the processing plant, cooled down and turned back into usable fuel.

When a customer goes to fill up their car, a pump placed at the bottom of the tank activates and starts sending gas up through a series of pipes and filters into the fuel dispenser. From there it flows into the fuel nozzle, which is perhaps the most interesting piece of the puzzle.

How fuel nozzle’s work

Back in the day, this would have been a simple valve releasing gas into the car. Now it is a mechanical work of art that makes it impossible to overfill a car.

As the fuel enters the nozzle, it pushes its way through a narrow opening. Small holes around the opening lead down a thin pipe to a small opening at the tip of the nozzle. As the fuel flows, a low pressure region forms here, thanks to the venturi effect. Because of this, air starts being sucked in through the narrow pipe and into the opening, where it mixes with the gasoline.

Another tube, also connected to the narrow opening, leads up to a small compartment containing a sealed membrane. This is where the magic happens.

When the lever gets pressed, it pivots around here and opens up a valve, allowing fuel to pass through. But the only thing holding this part in place is a set of ball bearings.

When your car is full, the fuel covers the hole at the tip of the nozzle. This cuts off the flow of air being sucked into the system, and so, the only other path to get more air is through the other tube, but it’s completely sealed.

And so this negative pressure sucks the air out of the sealed compartment, creating a vacuum and lifting up the membrane. The ball bearings are now free to drop, causing the whole lever system to fall, closing the valve and cutting off the flow of fuel.

After the 70’s, cars became more efficient and required less trips to fill up, and so the number of gas stations started to decline. But thanks to 100 years of engineering, gas stations became safe and mundane.