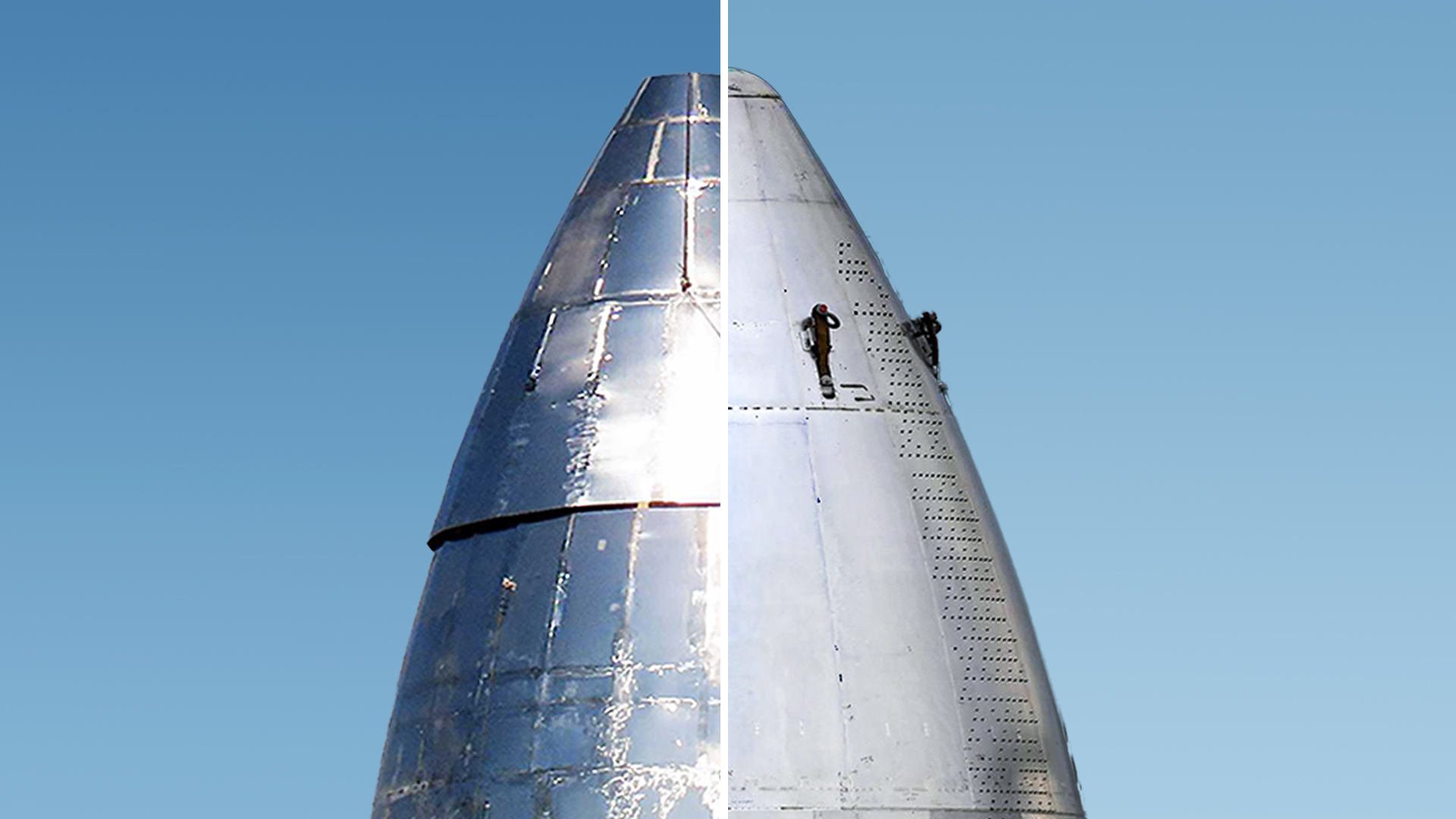

If you’ve been following Starship from the very beginning, you will know that it didn’t always look this good. The first Starship prototypes looked incredibly rough, not like something that could ever survive a journey into space. The Starships that SpaceX produce now look much more sophisticated, with smoother metal work and welds that are much less noticeable.

So how did Starship go from looking like this to this in just a few years? And will it ever look completely smooth and shiny like it does in the renders? To answer this question, we need to look at why Starship looks like this in the first place, more specifically, why it’s big and shiny instead of white and thin like most rockets.

Carbon fiber Starship

Starship wasn’t always destined to look like a 1940’s sci-fi rocket. In fact, it was originally meant to be made from carbon fiber and production had already begun in California. This seemed like the most logical plan since carbon fiber is extremely strong and SpaceX already had most of their workforce based in California. So it shocked everyone when a stainless steel Starship popped up in a small village in Texas.

But over time, people started to realize what a great decision this was. Although carbon fiber is very strong, it starts to break down at around 200 degrees. Therefore, it would require a very thick heatshield in order to survive the 1600 degree temperatures during multiple reentries.

Although stainless steel is heavier, it can deal with much higher temperatures, and so only a very thin heatshield would be required. Stainless steel is also much cheaper than carbon, costing just 3 dollars per kg compared to an incredible 150. But this wasn’t the first stainless steel rocket to be made. Back in the 60’s, NASA made an Atlas rocket out of incredibly thin stainless steel.

This was so thin, that unless the rocket was constantly pressurized, gravity alone would completely crush it. And it did! But even if SpaceX had gone with carbon fiber, it’s hard to see how Starship would have actually been made.

In order to manufacture carbon composites, the fibers have to be layered in a very specific way, in order for the material to be strong in every direction. Then the composites need to be cured in an enormous pressure oven. For Starship’s 9 meter wide sections, SpaceX would need an oven larger than anything that exists on Earth at the moment.

This is where stainless steel excelled. It could be put together quickly, using the most basic and affordable methods. And so, SpaceX began working on the world’s shiniest rocket. But for some reason, it wasn’t so shiny!

Stainless Steel Starship

One of the biggest challenges with the initial Starship prototypes was the welding. Initially, each ring was being made out of several sheets of 301 stainless steel, which were around 4.5mm thick. Don’t forget that the original Starship crew was contracted from a water tower company and didn’t have any experience with building rockets. So the welding standards were, well, not great. But what exactly is welding and why is it so difficult to get right?

Flux-core welding

The early Starship prototypes used a welding method called flux-core. With this method, a voltage is passed through a metallic wire which forms an arc between it and the metal, causing it to melt. The tip of the metallic wire also melts and falls into the now molten stainless steel, filling up any cracks or air bubbles.

With flux-core, the metal wire is surrounded by a solid material that burns and releases a protective gas around the weld. This protects the weld and stops it from reacting with the oxygen in our atmosphere, which would cause corrosion. This works well when you’re inside a controlled environment.

But SpaceX’s main problem at the time was that they didn’t really have a proper factory, just a fairly large tent. And so, with most of the welding being done outside by welders that had no rocket experience, it’s no surprise Starship looked so bad.

The welds on the first mark 1 prototype were heavily corroded, with cracks and rough edges on the surface. In order to improve these welds, SpaceX started grinding them down until they were flush with the surface. Although this seemed like a poor attempt to restore some shininess, this process was actually done to strengthen the welds.

These sharp edges and tiny cracks act as pressure points which could lead to much bigger cracks once Starship is pressurized. And so, grinding the surface removed these defects and reduced the chance of a weld failing. In theory, each weld should be as strong as the surrounding metal. But the initial Starship test proved that it wasn’t. Mark 1 exploded when one of the horizontal welds failed and sent the bulkhead flying.

And so, SpaceX brought in some major improvements to the next Starship prototype, SN1. Each ring was now made from thinner single sheets of stainless steel which required much less welding. They also moved from 301 to 304L stainless steel which was much more resistant to corrosion when welding.

TIP-TIG Welding

At this point, they also upgraded to TIP-TIG welding, which gave them more control over the welding arc, allowing the welder to tighten it up and weld much deeper into the metal. This produced much thinner welds and didn’t warp the surrounding metal nearly as much.

SpaceX also started to buy robotic welding machines from companies Liburdi and Kuka, similar to the ones seen in Tesla factories. With these upgrades, SpaceX automated a large chunk of the process and started to produce cleaner and more precise welds. They also began installing more stringers on the inside of Starship’s hull, to stop the metal from buckling under its own weight. But SpaceX didn’t stop there.

Laser welding

By now, SpaceX has likely moved onto laser welding for many of Starship’s sections. With laser welding, the heat is much more concentrated and goes deeper into the metal, allowing the ring segments to be welded in a single pass. But in order to really improve the strength of each weld, another process has to be done. You see, when Starship’s stainless steel is produced in its factory, it goes through a process called cold rolling.

This involves passing the metal through a series of rollers which compress it down and stretch out the grains in the metal. This makes the material stronger and harder. However, when Starship is welded, the heat causes the metal in that area to soften up again. This is where SpaceX’s giant planishing machine comes in.

Planishing involves hammering the welds down and compressing them until they match the hardness of the surrounding metal. This has the added benefit of smoothing the finish of the welds and improving their look. But will Starship ever have a completely smooth finish like a mirror?

To answer this, we need to go to Chicago to look at the famous Bean sculpture. Made from several stainless steel sheets, this structure went through an 8 month polishing process, involving a crew of 24 people using many different grades of sanding grit.

In order to do this on Starship, the entire body would need to go through this process to avoid having any visible lines around the welds, so it’s unlikely that SpaceX will ever do this. Either way, SpaceX is throwing everything into Starship and it’s amazing to see this project come together so quickly. Speaking of amazing projects.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.